Introduction

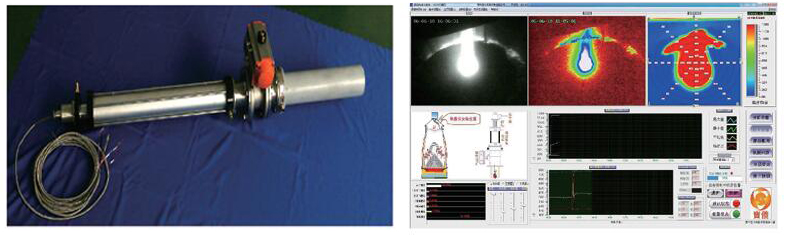

Two-cylinder high temperature camera system is especially designed for blast furnace. As we know the traditional blast furnace camera systems are all manual, operators should put probe out of furnace by hands, it will not only require lots of labour force, but also exist a big security risk, for the coal gas of furnace inside. And for the system, if the temperature is over, it only alarm but can not withdraw. Our system will solve these two problems, the detector will receive signal when over-temperature or over-pressure,then the auto-retraction system works whole system will withdraw automatically.

Features

Tight structure and well sealed probe

Pneumatic ball valve works automatically after probe withdraw

Both video camera and infrared camera are selectable

Temperature data saving, simulation temperature field analysis

Air purge device will help to clean probe head

Auto protection device under water cut off, air cut off and power cut off

Temperature parameters | Image parameters | ||

Temperature range | -50℃-1000℃ 600℃~1800℃ | Infrared camera resolution | 640*480/384*288 |

Accuracy | ±2%FS,repeat accuracy±2‰ | Video camera resolution | Max 1920*1080 |

Resolution | 1℃ | Infrared viewing angle | 9mm:60°*44° |

Emissivity | 0-0.99 | vision viewing angle | 100° |

Value mode | instant,peak and averaging | Communication mode | Coaxial video temperature control |

Object distance | 0.6~infinite meters | Max temperature inside furnace | 2000℃ |

Min. Object | >Φ5mm | Retraction system | Temperature, pressure,flow |

Power supply | 15~24VDC | Air inlet pressure | ≧0.3Mpa |

Power consumption | 150mA(max) | Air consumption | ≈20m3 |

output | 4~20mA、1~5V、 RS485 | Power consumption | Pneumatic 10W |