Brief introduction

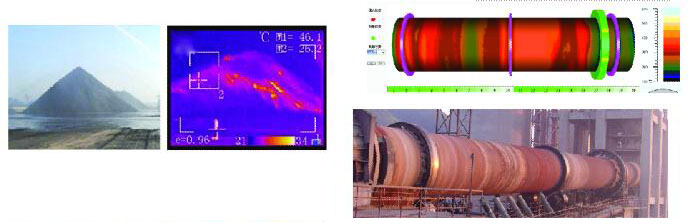

This system combines video camera and high-speed infrared scanner system, with full direction network PTZ, it will monitor a motionless object or mobile object at a big area all days. Typical application is using in rotary kiln , to monitor its shell temperature, surface condition and temperature field distribution for coal storage yard. In the meanwhile, the video camera will provide real time images to help operators find where is the monitored or damaged point, thus, they can make a quick responses. By this system, users can reduce their lost very effectively. And the 3D software will simulate coal field condition, setting temperature alarm to control the spray, to realize high temperature measurement and fight automatically, a real man-less operation.

Main applications

Rotary kiln, coal field spontaneous fire monitoring, forest fire, material conveyor, plants production line, thin film production line and etc.

Scanner indication | Camera PTZ indication | ||

Detector | HgCdTe | Sensor | 1/3 CMOS |

Temperature range | 200~350 ℃/ 70~550 ℃ | Network resolution | 2-mega pixel |

Scanning accuracy | 1024 point/S | Optical zoom | 5~10 times |

Scanning frequency | 20-150Hz | Compressed format | H.264 |

Scanning angel | 90° | Dynamic range | Wide dynamic |

Temperature accuracy | ±1%FS. repeat accuracy ±2‰ | Infrared light | 10-100 meters |

D:S | 450:1 | Network protocol | TCP/IP UDP |

Min.object | bigger than φ5mm | Horizontal rotation | 350° full direction |