The blast furnace camera system is a new designed product. It is mainly used for real-time monitoring of the blast furnace internal charge and rotary chute status. It can monitor the phenomenon of pipeline, collapsed material, sitting material and material surface deflection, which is convenient for the blast furnace operator to obtain the information of the furnace inside in time, to provide the basis for the upper blast furnace adjustment, thus creating conditions for the high production, high quality, low consumption and long life of the blast furnace.

The whole system adopts the latest ultra-low illumination infrared camera from abroad to ensure long-term operation under the top condition of the blast furnace. At the same time, the system has the functions of explosion-proof and gas leakage prevention.

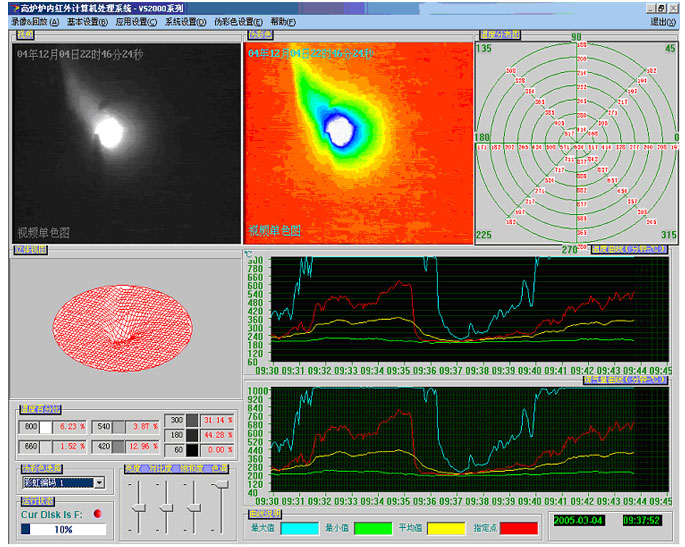

The blast furnace top temperature analysis system software independently developed by our company integrates image acquisition, video analysis and temperature analysis. It can timely and intuitively observe the temperature change in the blast furnace and record the temperature in a certain time or time period. Provide a direct basis for companies to solve related problems.

1. System Features

Lens operating temperature: The front can withstand temperatures of 1800℃

The high temperature detector is equipped with a dedicated infrared camera and special lens. The detector housing is a water-cooled gas-sealed protective sleeve with a front opening of ф2mm~ф5mm.

High temperature detection

The head is mounted on the wall of the high temperature furnace to avoid gas leakage in the blast furnace when the camera and lens are removed from the probe for inspection.

The system can work continuously for 24 hours under normal working conditions, and the service life can reach more than 5 years.

With infrared imaging, the image is clear.

With image information processing system and temperature measurement software.

By connecting the RS-485 communication card to the computer, the furnace top temperature is transmitted to the computer in real time, and the image and temperature changes in the furnace can be observed in time.

The image of furnace inside can be displayed on both the monitor and the computer.